Fuskar Flange Gama

Ƙarshen fuskar flange

Lambar ASME B16.5 tana buƙatar cewa fuskar flange (tasowa fuska da lebur fuska) tana da ƙayyadaddun ƙayyadaddun ƙayyadaddun yanayin don tabbatar da cewa wannan farfajiyar ta dace da gasket kuma tana ba da hatimi mai inganci.

Ana buƙatar ƙarewar serrated, ko dai mai ma'ana ko karkace, tare da tsagi 30 zuwa 55 a kowane inch da sakamakon rashin ƙarfi tsakanin inci 125 zuwa 500. Wannan damar domin daban-daban maki na surface gama da za a yi samuwa ta flange manufactures ga gasket lamba surface na karfe flanges.

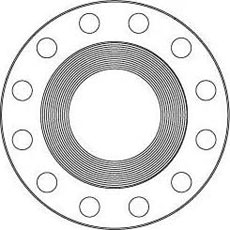

Hoton yana nuna rarrabuwar kawuna akan Fuskar da aka ɗaga.

Filayen da aka fi amfani da su

Kammala hannun jari

Mafi yadu amfani da kowane flange surface gama, domin a zahiri, ya dace da duk talakawa sabis yanayi. A ƙarƙashin matsawa, fuska mai laushi daga gasket za ta shiga cikin wannan ƙarewa, wanda ke taimakawa wajen haifar da hatimi, kuma ana haifar da babban matakin rikici tsakanin abubuwan da aka haɗa.

Ƙarshen waɗannan flanges ana samar da su ta hanyar radius 1.6 mm radius zagaye-noed kayan aiki a ƙimar ciyarwa na 0.8 mm kowane juyin juya hali har zuwa inch 12. Don masu girma dabam 14 inch kuma ya fi girma, an yi ƙarshen tare da 3.2 mm kayan aiki zagaye-hannu a abinci na 1.2 mm kowane juyin juya hali.

Spiral Serrated

Wannan kuma ci gaba ne ko tsintsiya madaurinki-daki, amma ya bambanta da gamawar haja a cikin cewa tsagi yawanci ana yin shi ta amfani da kayan aiki na 90-° wanda ke haifar da juzu'i na “V” tare da serration na kusurwa 45°.

Concentric Serrated

Kamar yadda sunan ke nunawa, wannan ƙarewa ya ƙunshi ramuka masu ma'ana. Ana amfani da kayan aiki na 90° kuma an raba serrations daidai da fuska.

Gama Lafiya

Wannan ƙarewa ba ya nuna alamun kayan aiki na gani. Ana amfani da waɗannan abubuwan da aka gama don gaskets tare da fuskokin ƙarfe kamar su jaket biyu, ƙarfe mai lebur da ƙura. Filaye masu santsi suna haɗe don ƙirƙirar hatimi kuma sun dogara da shimfiɗar fuskokin da ke gaba da juna don yin hatimi. Ana samun wannan yawanci ta hanyar samun saman tuntuɓar gasket ta hanyar ci gaba (wani lokacin da ake kira phonographic) karkataccen tsagi wanda aka samar ta hanyar radius mai zagaye na 0.8 mm a ƙimar ciyarwar 0.3 mm a kowace juyin juya hali tare da zurfin 0.05 mm. Wannan zai haifar da rashin ƙarfi tsakanin Ra 3.2 da 6.3 micrometers (125 – 250 micro inch).

Bayanin Mawallafin…

KYAU SAUKI

Shin ya dace da gasket na karkace da gasket ɗin da ba na ƙarfe ba?

Don wane irin aikace-aikace ne wannan nau'in?

Ana yawan yin tambayoyin da ke sama. Ina ƙoƙarin bayar da amsa daidai.

Smooth gama flanges sun fi na kowa don ƙananan matsa lamba da/ko manyan bututun diamita kuma da farko an yi niyya don amfani da ƙarfe mai ƙarfi ko karkace gaskets.

Ana samun ƙayyadaddun ƙaƙƙarfan ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun kayan aiki ko kayan haɗin gwiwa ban da flanges na bututu. Lokacin aiki tare da ƙarewa mai santsi, yana da mahimmanci a yi la'akari da yin amfani da gasket na bakin ciki don rage tasirin raɗaɗi da sanyi. Ya kamata a lura, duk da haka, cewa duka gaskat mai bakin ciki da kuma ƙarewa mai santsi, a ciki da kansu, suna buƙatar ƙarfin matsawa mafi girma (watau karfin juyi) don cimma hatimin.

Wataƙila kun ga wannan sharhi:

Machining na gasket fuskokin flanges zuwa santsi gama na Ra = 3.2 - 6.3 micrometer

(= 125 - 250 microinchesAARH)

AARHyana tsaye ga Matsakaicin Tsawon Tsawon Lantarki. Ana amfani da shi don auna roughness (maimakon santsi) na saman. 125AARHyana nufin 125 micro inci zai zama matsakaicin tsayi na sama da ƙasa na saman.

63 AARHAn kayyade don Haɗin Nau'in Ring.

125-250AARH(ana kiranta santsi gamawa) an ayyana shi don Ƙaƙwalwar Rauni Gasket.

250-500AARH(ana kira stock gama) an kayyade ga taushi gaskets kamar NON asbestos, Graphite zanen gado, Elatomers da dai sauransu Idan muka yi amfani da m gama ga taushi gaskets isa "cizo sakamako" ba zai faru da kuma saboda haka hadin gwiwa iya ci gaba yayyo.

Wani lokaciAARHana kuma magana a kaiRawanda ke tsaye ga Roughness Average kuma yana nufin iri ɗaya.

Lokacin aikawa: Yuli-06-2020