Menene Flange?

Janar Flanges

Flange hanya ce ta haɗa bututu, bawul, famfo da sauran kayan aiki don samar da tsarin bututun. Hakanan yana ba da damar sauƙi don tsaftacewa, dubawa ko gyarawa. Flanges yawanci ana walda su ko kuma a dunƙule su. Ana yin mahaɗar flanged ta hanyar haɗa flanges biyu tare da gasket tsakanin su don samar da hatimi.

Nau'in Flanges

Mafi yawan nau'ikan flange da ake amfani da su a cikin masana'antar Petro da masana'antar sinadarai sune:

- Welding Neck Flange

- Zamewa Kan Flange

- Socket Weld Flange

- Lap Joint Flange

- Flange mai zare

- Flange makafi

![]() Duk nau'ikan ban da Haɗin Haɗin gwiwa na Lap ana ba da su tare da haɓakar fuskar flange.

Duk nau'ikan ban da Haɗin Haɗin gwiwa na Lap ana ba da su tare da haɓakar fuskar flange.

Flanges na musamman

Sai dai mafi yawan amfani da daidaitattun flanges, har yanzu akwai adadin flanges na musamman kamar:

- Farashin Flanges

- Dogon Welding Neck Flanges

- Weldoflange / Nipoflange

- Fadada Flange

- Rage Flange

![]()

Materials don Flanges

Ana ƙera flanges bututu a cikin duk nau'ikan kayan kamar bakin karfe, simintin ƙarfe, aluminum, tagulla, tagulla, filastik da sauransu.

Bugu da kari, flanges, kamar kayan aiki da kuma bututu, don takamaiman dalilai, wani lokacin a ciki sanye take da yadudduka na kayan da mabanbanta ingancin kamar flanges kansu, wanda yake "layi flanges".

Abubuwan da ke cikin flange, an saita su a lokacin zaɓin bututu, a mafi yawan lokuta, flange na abu ɗaya ne kamar bututu.

Duk flanges, da aka tattauna akan wannan gidan yanar gizon sun faɗi ƙarƙashin ka'idodin ASME en ASTM, sai dai in an nuna. ASME B16.5 yana kwatanta girma, jure juzu'i da dai sauransu da ASTM halaye daban-daban na kayan.

Girman Flanges

Kowane flange ASME B16.5 yana da adadin daidaitattun girma. Idan mai zane a Japan ko mai shirya aiki a Kanada ko mai bututun mai a Ostiraliya yana magana game da walƙiya Neck flange NPS 6, Class 150, Jadawalin 40 ASME B16.5, to, ya wuce flange wanda a cikin hoton da ke ƙasa an nuna shi. .

Idan an ba da umarnin flange, mai siyarwa yana son sanin ingancin kayan. Misali ASTM A105 jabun carbon karfe flange ne, yayin da A182 jabun bakin karfe ne.

Don haka, a cikin tsari daidai ga mai siyarwa dole ne a ƙayyade ma'auni biyu:

Welding Neck Flange NPS 6, Class 150, Jadawalin 40, ASME B16.5 / ASTM A105

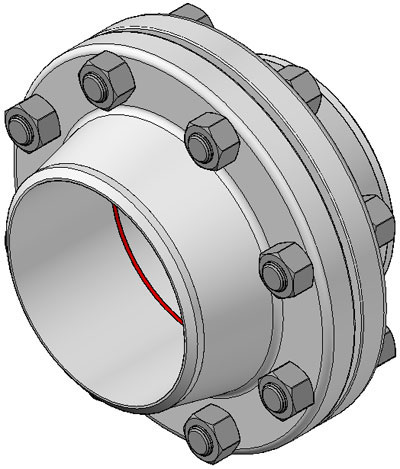

Flange na sama yana da ramuka 8, da madaidaicin walda na digiri 37.5 (da'irar ja). Duk girman da aka bayar suna cikin millimeters. Fuskar da aka ɗaga (RF) baya buƙatar ƙayyade, saboda ASME B16.5, kowane flange daidai ne da aka kawo tare da ɗaga fuska. Sai kawai wani ƙira na daban (Ring Type Joint (RTJ), Flat Face (FF) da sauransu), yakamata a ƙayyade.

Haɗin Flange da aka rufe

Haɗin flange da aka kulle shine hadaddun haɗe-haɗe na abubuwa da yawa (Flange, Bolts, Gasket, Process, Temperature, Matsi, Matsakaici). Duk waɗannan abubuwa daban-daban suna da alaƙa da juna kuma suna dogara ga juna don samun sakamako mai nasara.

Amintaccen haɗin gwiwar flanged ya dogara sosai akan ingantaccen sarrafa tsarin yin haɗin gwiwa.

Haɗin haɗin flange na al'ada

Ciro daga littafin John H. Bickford, “Gabatarwa ga Zane da Halayen Ƙungiyoyin Ƙarfafawa”:

Cewa duk mahimmancin ƙwanƙwasa wanda ke haɗa haɗin gwiwa tare - kuma ba tare da wanda ba za a sami haɗin gwiwa ba - ba a ƙirƙira shi ta hanyar mai tsara haɗin gwiwa ba, ko kuma ta sassa masu inganci. Makaniki ne ya kirkiro shi a wurin aiki, ta amfani da kayan aiki, hanyoyin aiki, da yanayin aiki da muka ba shi… Kuma ƙari: Na ƙarshe, mai mahimmanci mahaliccin ƙarfin shine makaniki, kuma lokacin ƙirƙirar shine lokacin haɗuwa. Don haka yana da matukar muhimmanci a gare mu mu fahimci wannan tsari.

Masana'antu sun gane mahimmancin yanayin shigarwa da taro na shekaru da yawa.

A Turai, an ba da fifiko kan tabbatar da cewa kwararrun kwararru da kwararrun kwararru ne ke aiwatar da hadin gwiwa kuma hakan ya haifar da buga ka'idar Fasaha ta Turai: TS EN 1591 Sashe na 4 mai taken "Flanges da haɗin gwiwar su. Sharuɗɗan ƙira don haɗin haɗin madauwari madauwari ta flange. Cancantar cancantar ma'aikata a cikin haɗuwar haɗin gwiwa da aka haɗa da kayan aiki waɗanda ke ƙarƙashin Jagoran Kayan Aikin Matsi (PED)”.

Ma'aunin yana ba da wata hanya don horarwa da kima na ƙwararrun masu fasaha waɗanda ke da hannu wajen yinwa da karya haɗin gwiwar flange kuma ana iya kallon su azaman kwatankwacin horon da ake buƙata don masu walda waɗanda ke da alaƙa da aikin jirgin ruwa. Bugawar ta yana nuna mahimmancin da aka sanya akan ingantaccen tsarin yin haɗin gwiwa don tabbatar da aikin ba tare da ɗigo ba daga flange.

Gasket ɗin yana ɗaya daga cikin dalilai da yawa haɗin haɗin haɗin flange da aka kulle zai iya zubo.

Ko da a lokacin da duk hadaddun abubuwan da ke da alaƙa na haɗin haɗin haɗin gwiwar haɗin gwiwa suna aiki cikin jituwa daidai, ɗayan mafi mahimmancin abin da ke haifar da nasara ko gazawar haɗin haɗin flange ɗin za a ba da hankali ga ingantaccen shigarwa da hanyoyin haɗuwa ta mutumin da ke shigar da gasket. . Idan an yi shi da kyau, taron zai kasance babu ɗigo don tsawon rayuwa da aka yi niyya.

Bayanin Mawallafin…

Haɗi mai banƙyama tare da haɗin welded

Babu wasu ƙa'idodi waɗanda ke ayyana ko ana iya amfani da haɗin flange ko a'a.

A cikin sabon ginin masana'anta al'ada ce don rage haɗin haɗin flange, saboda walda ɗaya kawai ake buƙata don haɗa bututu guda biyu. Wannan ceton halin kaka na biyu flanges, da gasket, da Stud Bolts, na biyu weld, farashin NDT na biyu weld, da dai sauransu.

Wasu rashin amfani na haɗin flange:

- Kowane haɗin flange na iya zubewa (wasu mutane suna da'awar cewa haɗin flange ba zai taɓa zama hujjar zubar da kashi 100 ba).

- Na'urorin bututu masu tuƙi suna buƙatar ƙarin sarari (kawai ka yi tunanin tarin bututun).

- Insulation na tsarin bututun flanged ya fi tsada (musamman iyakoki na flange).

Tabbas, haɗin flange yana da fa'idodi masu yawa; wasu misalan:

- Wani sabon layi zai iya ƙunsar spools da yawa kuma ana iya kera shi a cikin taron bita.

- Ana iya haɗa wannan spools na bututu a cikin shuka ba tare da buƙatar waldawa ba.

- NDO (X-ray, gwajin Hydro da dai sauransu) a cikin shuka ba lallai ba ne, saboda an yi hakan a cikin bitar.

- Fashewa da fenti a cikin shuka ba lallai ba ne, saboda ko da an yi wannan a cikin bita

(kawai lalacewar fenti yayin shigarwa ya kamata a gyara).

Kamar yadda yake da abubuwa da yawa, komai yana da fa'ida da rashin amfaninsa.

Lokacin aikawa: Mayu-30-2020