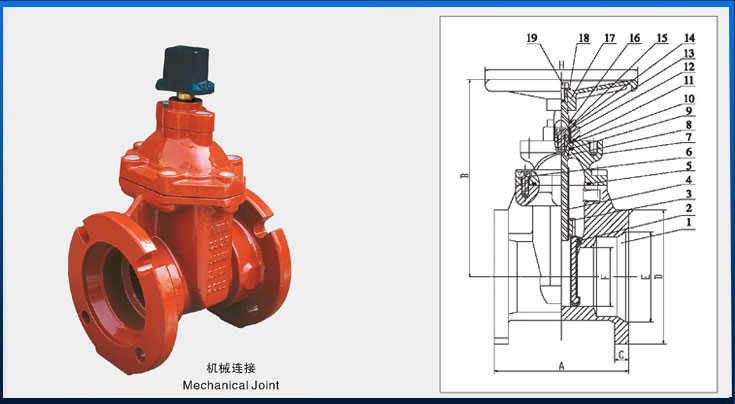

Nama: Sambungan Mekanikal Berakhir NRSInjap Gerbang Duduk Berdaya TahanKelulusan s-AWWA C509-UL/FM

1.Standard: Menepati AWWA C509

2.Bahan: Besi mulur

3. Tekanan Biasa: 250PSI/300PSI

4. Saiz: 2″-16″

| Butiran produk: |

| 250PSI AWWA C509 Sendi Mekanikal Badan Besi Mengakhiri Baji Berdaya TahanInjap Pintus | Bonet Berbolted ?Batang Tidak Meningkat ?Baji Berdaya Tahan ?MJ Berakhir

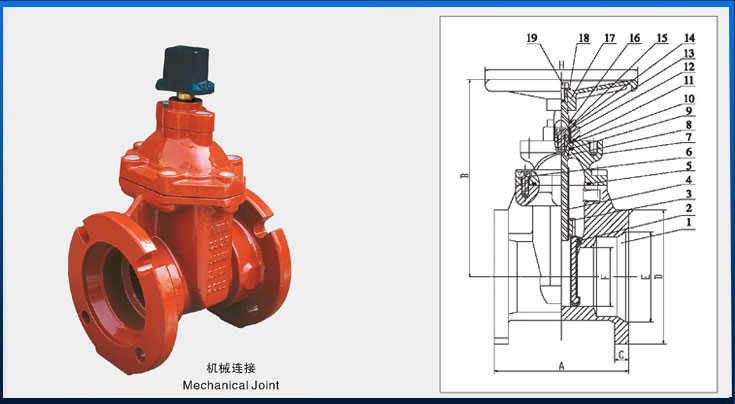

250 PSI/17.2 Bar Tekanan Kerja Sejuk Tanpa Kejutan

MEMATUHI AWWA C509 | |  | | | BAHAGIAN | SPESIFIKASI | | 1. | Badan Injap | Besi mulur ASTM A 536 | | 2. | Baji Berdaya tahan | Besi mulur ASTM A 536/EPDM ASTM D 2000 | | 3. | Kacang Baji | Gangsa ASTM B 584 UNS C83600 | | 4. | Batang | Gangsa ASTM B 150 UNS C61400 | | 5. | Bonet Gasket | EPDM ASTM D 2000 | | 6. | Skru Bonet | Keluli Aloi ASTM A 574M Bersalut Zink | | 7. | Bonet | Besi mulur ASTM A 536 | | 8. | Cincin O Utama Batang | EPDM ASTM D 2000 | | 9. | Pencuci Tujah Batang (bawah) | Gangsa ASTM B 584 UNS C83600 | | 10. | Pencuci Tujah Batang (atas) | Keluli Tahan Karat ASTM A 276 UNS S41000 | | 11. | Cincin O Pengedap Kelenjar | EPDM ASTM D 2000 | | 12. | Sesendal Stem Seal | Gangsa ASTM B 584 UNS C83600 | | 13. | Cincin O Sekunder Batang (2) | EPDM ASTM D 2000 | | 14. | Bebibir Kelenjar | Besi mulur ASTM A 536 | | 15. | Skru Bebibir Kelenjar | Keluli Aloi ASTM A 574M Bersalut Zink | | 16. | Pengelap Cincin Batang | EPDM ASTM D 2000 | | 17. | Nat Operasi Segiempat | Besi tuang ASTM A 126-B | | 17A. | Roda Tangan (Pilihan) | Besi mulur ASTM A 536 | | 18. | Pencuci Rata | Bersalut Zink Keluli Karbon | | 19. | skru | Keluli Aloi ASTM A 574M Bersalut Zink | | Saiz | Dimensi | Bolt

Bulatan | Bebibir

berlubang | Berpusing

Untuk Membuka | Berat badan | | A | B | C | D | E | F | H | | Dalam. | mm. | Dalam. | mm. | Dalam. | mm. | Dalam. | mm. | Dalam. | mm. | Dalam. | mm. | Dalam. | mm. | Dalam. | mm. | Dalam. | mm. | Lbs. | Kg. | | 3 | 80 | 8.0 | 203 | 12.7 | 322 | 0.94 | 24 | 7.7 | 196 | 4.9 | 126 | 3.1 | 80 | 10.2 | 260 | 6.19 | 157 | 4 | 10.8 | 43 | 20 | | 4 | 100 | 10.0 | 254 | 13.5 | 344 | 1.00 | 26 | 9.1 | 232 | 6.0 | 153 | 3.9 | 100 | 10.2 | 260 | 7.50 | 191 | 4 | 13.0 | 70 | 36 | | 6 | 150 | 11.5 | 292 | 17.4 | 441 | 1.06 | 27 | 11.1 | 283 | 8.1 | 206 | 5.9 | 150 | 14.8 | 375 | 9.50 | 241 | 6 | 15.7 | 112 | 51 | | 8 | 200 | 11.5 | 292 | 20.8 | 529 | 1.12 | 28 | 13.4 | 340 | 10.3 | 261 | 7.9 | 200 | 14.8 | 375 | 11.75 | 298 | 6 | 17.3 | 170 | 77 | | 10 | 250 | 13.0 | 330 | 24.2 | 614 | 1.18 | 30 | 15.7 | 400 | 12.3 | 313 | 9.8 | 250 | 15.7 | 400 | 14.00 | 356 | 8 | 21.4 | 267 | 121 | | 12 | 300 | 14.0 | 356 | 27.6 | 700 | 1.25 | 32 | 18.0 | 456 | 14.4 | 367 | 11.8 | 300 | 19.7 | 500 | 16.25 | 413 | 8 | 25.3 | 388 | 176 | | 14 | 350 | 15.0 | 381 | 31.8 | 807 | 1.38 | 35 | 20.3 | 516 | 16.5 | 420 | 13.8 | 350 | 19.7 | 500 | 18.74 | 476 | 12 | 30 | 550 | 250 | | 16 | 400 | 16.0 | 406 | 34.3 | 870 | 1.46 | 37 | 22.6 | 573 | 18.6 | 473.5 | 15.7 | 400 | 19.7 | 500 | 21.22 | 539.5 | 16 | 34 | 726 | 330 | | | |

Sebelumnya: Injap Semak Dwi Plat Jenis Wafer-ANSI CL125-150 Seterusnya: Camlock Coupling Type DP