Flange Face Yamaliza

Kumaliza kwa nkhope ya Flange

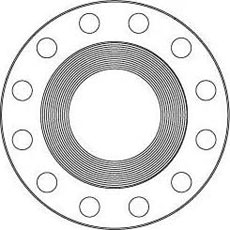

Khodi ya ASME B16.5 imafuna kuti nkhope ya flange (nkhope yokwezeka ndi nkhope yathyathyathya) ikhale ndi roughness yeniyeni kuti izi zitheke kuti zigwirizane ndi gasket ndikupereka chisindikizo chapamwamba.

Kutsirizitsa kopindika, kaya kokhazikika kapena kozungulira, kumafunika ndi 30 mpaka 55 grooves pa inchi ndipo zotsatira zake zimakhala zowawa pakati pa 125 ndi 500 mainchesi yaying'ono. Izi zimalola kuti mitundu yosiyanasiyana ya kumaliza ikhale yopezeka ndi opanga ma flange kuti agwirizane ndi gasket pamwamba pazitsulo zachitsulo.

Chithunzicho chikuwonetsa kumaliza kokhazikika pankhope yokwezeka.

Zomwe zimagwiritsidwa ntchito kwambiri ndi Surfaces

Kutha Kwamasheya

Zomwe zimagwiritsidwa ntchito kwambiri pamapeto aliwonse amtundu wa flange, chifukwa kwenikweni, ndizoyenera pazinthu zonse wamba. Pansi pa kuponderezedwa, nkhope yofewa kuchokera ku gasket idzalowetsedwa kumapeto uku, zomwe zimathandiza kupanga chisindikizo, ndipo kumenyana kwakukulu kumapangidwa pakati pa malo okwera.

Mapeto a ma flangeswa amapangidwa ndi chida cha mphuno yozungulira ya 1.6 mm pamlingo wodyetsa wa 0.8 mm pakusintha mpaka mainchesi 12. Kwa kukula kwa mainchesi 14 ndi kukulirapo, mapeto ake amapangidwa ndi chida champhuno cha 3.2 mm pa chakudya cha 1.2 mm pakusintha.

Spiral Serrated

Iyinso ndi njira yopitilira kapena phonographic spiral groove, koma imasiyana ndi kumaliza kwake chifukwa poyambira nthawi zambiri amapangidwa pogwiritsa ntchito chida cha 90-° chomwe chimapanga geometry ya "V" yokhala ndi 45 ° angled serration.

Concentric Serrated

Monga momwe dzinalo likusonyezera, mapetowa amapangidwa ndi ma grooves ozungulira. Chida cha 90 ° chimagwiritsidwa ntchito ndipo ma serrations amagawidwa mofanana kumaso.

Smooth Finish

Chomaliza ichi sichimawonetsa zizindikiro zowoneka bwino za chida. Zotsirizirazi zimagwiritsidwa ntchito ngati ma gaskets okhala ndi zitsulo zoyang'ana ngati ma jekete awiri, chitsulo chosanja ndi chitsulo. Malo osalala amagwirizana kuti apange chisindikizo ndipo amadalira kusalala kwa nkhope zotsutsana kuti agwire chisindikizo. Izi zimatheka chifukwa chokhala ndi gawo lolumikizana ndi gasket lomwe limapangidwa ndi spiral groove (yomwe nthawi zina imatchedwa phonographic) yopangidwa ndi chida cha 0.8 mm radius round-nosed chida pamlingo wa 0.3 mm pa revolution ndi kuya kwa 0.05 mm. Izi zidzabweretsa roughness pakati pa Ra 3.2 ndi 6.3 micrometers (125 - 250 inchi yaying'ono).

Ndemanga za Wolemba…

AMATSIRIZA AMAKHALA

Kodi ndiyoyenera spiral gasket ndi non metallic gasket?

Ndi mtundu wanji wa ntchito wamtunduwu?

Mafunso omwe ali pamwambawa amafunsidwa kawirikawiri. Ndimayesetsa kupereka yankho lolondola.

Ma Flanges osalala amakhala ofala kwambiri pamapaipi otsika komanso/kapena akulu akulu ndipo amapangidwa kuti azigwiritsidwa ntchito ndi zitsulo zolimba kapena ma spiral bala gaskets.

Zotsirizira zosalala nthawi zambiri zimapezeka pamakina kapena zolumikizirana zopindika kupatula zitoliro. Pogwira ntchito yosalala, ndikofunikira kuganizira kugwiritsa ntchito gasket yocheperako kuti muchepetse zotsatira za kukwapula ndi kuzizira. Komabe, ziyenera kudziwidwa kuti gasket yocheperako komanso kumaliza kosalala, mkati mwawokha, zimafunikira mphamvu yopondereza (ie torque ya bawuti) kuti ikwaniritse chisindikizocho.

Mwinamwake mudawonapo ndemanga iyi:

Machining a gasket nkhope za flanges kuti yosalala mapeto a Ra = 3.2 - 6.3 micrometer

(= 125 - 250 mainchesiAARH)

AARHimayimira Arithmetic Average Roughness Height. Amagwiritsidwa ntchito poyeza kukhwimitsa (m'malo mosalala) kwa malo. 125AARHzikutanthauza kuti mainchesi 125 ang'onoang'ono adzakhala kutalika kwapakati ndi kutsika kwapamtunda.

63 AARHimatchulidwira Malumikizidwe a Mtundu Wa mphete.

125-250AARH(amatchedwa kumaliza kosalala) amatchulidwa kwa Spiral Wound Gaskets.

250-500AARH(amatchedwa stock finish) amatchulidwa kwa gaskets zofewa monga NON Asbestos, Graphite mapepala, Elastomers etc. Ngati tigwiritsa ntchito yosalala gaskets zofewa gaskets zokwanira "kuluma zotsatira" sizidzachitika choncho olowa akhoza kukhala kutayikira.

Nthawi zinaAARHimatchedwanso kutiRazomwe zimayimira Roughness Average ndipo zimatanthauza zomwezo.

Nthawi yotumiza: Jul-06-2020