Ubuso beFlange Gqiba

Ukugqiba ubuso beFlange

Ikhowudi ye-ASME B16.5 idinga ukuba ubuso be-flange (ubuso obuphakanyisiweyo kunye nobuso obunqamlekileyo) bunobunzima obuthile bokuqinisekisa ukuba lo mhlaba uyahambelana ne-gasket kwaye unikeze isitywina esiphezulu.

Isiphelo esirhwexulweyo, nokuba sigxile okanye sijiko, siyafuneka nge 30 ukuya 55 yegrooves nge-intshi nganye kunye nesiphumo sokurhabaxa phakathi kwe 125 kunye ne 500 i-intshi ze micro. Oku kuvumela amabakala ahlukeneyo okugqitywa komphezulu ukuba enziwe afumaneke ngabavelisi be-flange kumphezulu wokudibanisa i-gasket yeeflange zentsimbi.

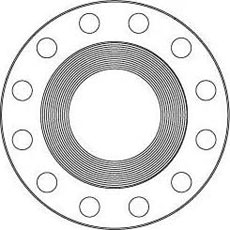

Umfanekiso ubonisa ukugqitywa kwe-serrated kuBuso obuphakanyisiweyo.

Eyona Mibuso isetyenziswa kakhulu

Ukuphela Kwempahla

Eyona nto isetyenziswa kakhulu kuyo nayiphi na indawo yokugqiba umphezulu weflange, kuba ngokwenyani, ilungele zonke iimeko zenkonzo eqhelekileyo. Ngaphantsi kokunyanzeliswa, ubuso obuthambileyo obuvela kwi-gasket buya kufakwa kule ngqungquthela, enceda ukudala isitywina, kunye nenqanaba eliphezulu lokungqubuzana kuveliswa phakathi kweendawo zokukhwelana.

Ukugqiba kwezi flange ziveliswa sisixhobo se-1.6 mm serediyasi esijikeleza ngempumlo kumyinge wokutya we-0.8 mm nge-revolution ukuya kwi-intshi eyi-12. Ubukhulu be-intshi ye-14 nangaphezulu, ukugqiba kwenziwa nge-3.2 mm isixhobo esijikelezileyo esinempumlo kwi-feed ye-1.2 mm nge-revolution.

Spiral Serrated

Oku kukwangumjelo ojikelezayo oqhubekayo okanye wephonografi, kodwa iyahluka kwisiphelo sesitokhwe kuba igroove iveliswa kusetyenziswa isixhobo esingu-90-° esidala ijiyometri “V” ene-45° engile serration.

Concentric Serrated

Njengoko igama libonisa, oku kugqitywa kuqulethwe ziigrooves ezigxininisiweyo. Isixhobo se-90 ° sisetyenziswa kwaye iiserati zihlukaniswe ngokulinganayo ebusweni.

Gqiba kakuhle

Oku kugqitywa kubonisa akukho zixhobo ezibonakalayo ezibonakalayo. Ezi zinto zigqityiweyo ziqhele ukusetyenziselwa iigaskets ezineentsimbi ezijonge ezantsi ezinje ngebhatyi ephindwe kabini, intsimbi ecaba kunye nentsimbi. Imiphezulu egudileyo idibana ukwenza itywina kwaye ixhomekeke kumcaba wobuso obuchasayo ukwenza itywina. Oku kudla ngokuphunyezwa ngokuba nomphezulu wokudityaniswa kwe-gasket owenziwe ngokuqhubekayo (maxa wambi okubizwa ngokuba yiphonografi) spiral groove eveliswa sisixhobo esinempumlo ejikelezileyo eyi-0.8 mm kwireyidi yomyinge we-0.3 mm kwi-revolution nganye enobunzulu be-0.05 mm. Oku kuya kubangela uburhabaxa phakathi kweRa 3.2 kunye ne-6.3 micrometers (125 - 250 intshi encinci).

Amagqabantshintshi oMbhali...

GQIBELA EZULILEYO

Ngaba ifanelekile kwi-spiral gasket kunye ne-non metallic gasket?

Ngoluphi uhlobo lwesicelo olu hlobo?

Le mibuzo ingasentla idla ngokubuzwa. Ndizama ukunika impendulo echanekileyo.

Iiflange zokugqiba ezigudileyo zixhaphake kakhulu kuxinzelelo oluphantsi kunye/okanye imibhobho emikhulu edayamitha kwaye ijolise ikakhulu ukusetyenziswa ngentsimbi eqinileyo okanye iigasthi zamanxeba ajiyileyo.

Ukugqitywa okugudileyo kuvame ukufunyanwa koomatshini okanye kumalungu aneflanged ngaphandle kweeflange zemibhobho. Xa usebenza ngokugqitywa okugudileyo, kubalulekile ukuqwalasela ukusebenzisa i-gasket encinci ukunciphisa imiphumo ye-creep and cold flow. Kufuneka kuqatshelwe, nangona kunjalo, ukuba zombini i-gasket ebhityileyo kunye nokugqiba okugudileyo, ngaphakathi kwaye ngokwabo, kufuna amandla aphezulu oxinzelelo (okt torque yebholiti) ukufezekisa itywina.

Usenokuba uwabonile la mazwi:

Ukucutshungulwa kobuso be-gasket yeeflange ukuya kwisiphelo esigudileyo seRa = 3.2 - 6.3 micrometer

(= 125 – 250 microintshiAARH)

AARHimele i-Arithmetic Average Roughness Height. Isetyenziselwa ukulinganisa uburhabaxa (kunokuba bugude) bemiphezulu. 125AARHkuthetha ukuba i-intshi ze-125 micro ziya kuba ngumphakamo oqhelekileyo wokunyuka nokuhla komphezulu.

63 AARHixelwa kwiZidibaniselwano zoNxibelelwano lweNdasa.

125-250AARH(kubizwa ngokuba kugqityiwe okugudileyo) kucacisiwe kwi-Spiral Wound Gaskets.

250-500AARH(ibizwa ngokuba yi-stock finish) icaciswa kwiigaskithi ezithambileyo ezifana ne-NON Asbestos, amaphepha eGraphite, ii-Elastomers njl.njl. Ukuba sisebenzisa ukugqiba okugudileyo kwiigaskiti ezithambileyo ngokwaneleyo "isiphumo sokuluma" asiyi kwenzeka kwaye ngenxa yoko umdibaniso unokuphuhlisa ukuvuza.

Ngamaxesha athileAARHikwabizwa ngokubaRaemele i-Roughness Average kwaye ithetha into enye.

Ixesha lokuposa: Jul-06-2020