Isingeniso ku-Check valves

Ama-valve okuhlola ama-automatic valves avuleka ngokugeleza okuya phambili futhi avale ngokugeleza okubuyela emuva.

Ukucindezela koketshezi oludlula ohlelweni kuvula i-valve, kuyilapho ukuguqulwa kokugeleza kuzovala i-valve. Ukusebenza okuqondile kuzohluka kuye ngohlobo lwe-Check valve mechanism. Izinhlobo ezivame kakhulu zamavalvu okuhlola ukushwibeka, ukuphakamisa (ipiston nebhola), uvemvane, ima kanye nediski etshekisayo.

Izinhlobo zama-valve okuhlola

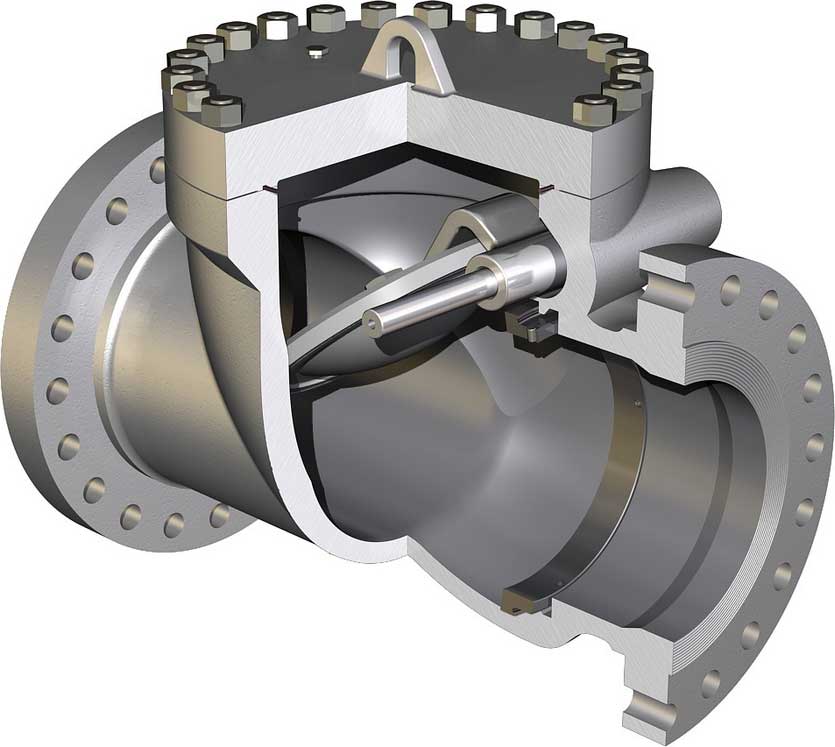

I-Swing Check valve

I-vasic swing Check valve iqukethe umzimba wevalvu, ibhonethi, nediski exhunywe kuhinji. Idiski isuke isuka ku-valve-seat ukuze ivumele ukugeleza iye phambili, futhi ibuyela ku-valve-seat lapho ukugeleza komfula kumisiwe, ukuvimbela ukugeleza emuva.

I-disc ohlotsheni lokushwibeka Hlola i-valve ayiqondiswanga njengoba ivuleka noma ivaleka ngokugcwele. Kunemiklamo eminingi yediski nezihlalo etholakalayo, ukuze kuhlangatshezwane nezidingo zezinhlelo zokusebenza ezahlukene. I-valve ivumela ukugeleza okugcwele, okungavinjelwe futhi ivale ngokuzenzakalelayo njengoba ukucindezela kuncipha. Lawa ma-valve avalwa ngokuphelele lapho ukugeleza kufinyelela ku-zero, ukuze kuvinjelwe ukugeleza emuva. I-turbulence kanye nokwehla kwengcindezi ku-valve kuphansi kakhulu.

Lift Check valve

Idizayini yesihlalo se-lift-Check valve ifana ne-Globe valve. I-disc ngokuvamile isesimweni se-piston noma ibhola.

I-Lift Check valves ifaneleka ngokukhethekile isevisi yokucindezela okukhulu lapho isivinini sokugeleza siphezulu. Kuma-lift Hlola ama-valve, idiski iqondiswa kahle futhi ingena kahle kudeshibhothi. Amavalvu okuhlola afanele ukufakwa emigqeni yamapayipi evundlile noma eqondile ageleza phezulu.

Ukugeleza ukuphakamisa Hlola ama-valve kufanele ahlale ngezansi kwesihlalo. Njengoba ukugeleza kungena, i-piston noma ibhola liphakanyiswa ngaphakathi kweziqondiso ukusuka esihlalweni ngokucindezela kokugeleza okuya phezulu. Uma ukugeleza kuma noma kuhlehla, ipiston noma ibhola liphoqelelwa esihlalweni sevalvu kukho kokubili ukugeleza okusemuva namandla adonsela phansi.

Isikhathi sokuthumela: May-06-2020