Isingeniso kumavalvu e-Pressure Seal

I-Pressure Seal Valves

Ukwakhiwa kwe-pressure seal kwamukelwa kuma-Valves ensizakalo yokucindezela okuphezulu, okuvamise ukudlula amabha angaphezu kuka-170. Isici esiyingqayizivele mayelana ne-Bonnet ye-pressure seal ukuthi amajoyinti eBonnet omzimba ayathuthuka njengoba ingcindezi yangaphakathi kuValve ikhula, uma kuqhathaniswa nezinye izakhiwo lapho ukwanda kwengcindezi yangaphakathi kuvame ukudala ukuvuza esilinganisweni somzimba-Ibhonethi.

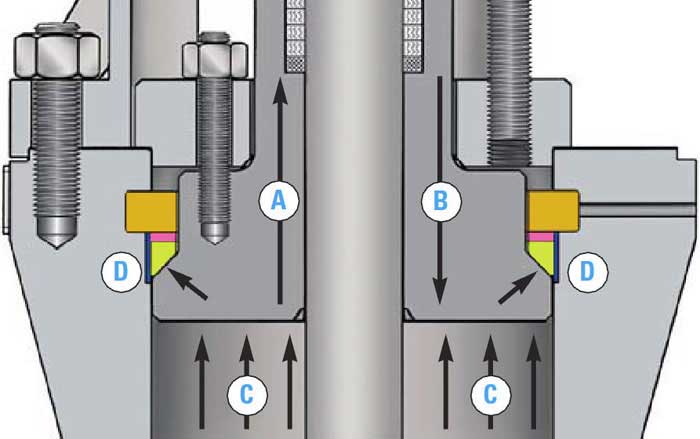

Umklamo wophawu lokucindezela

- I-A/B - Ukuthambekela kwebhonethi ukuya phezulu noma phansi njengoba ingcindezi ishintsha

- C - Ukucindezela kwesistimu

- D - Amandla okuvalwa ngenxa yengcindezi

Lapho ingcindezi yangaphakathi iphezulu, amandla okuvala ayanda. Ukuqaqa kalula kwenziwa kwenzeke ngokuphonsa ukuhlangana kweBhonethi endaweni yomzimba futhi kukhiphe izindandatho zokuphonswa ezinezingxenye ezine ngokusebenzisa iphinikhodi.

Ngokuthembela ezimisweni zokuklama ezilula, Amavaluvu ophawu lokucindezela afakazele amandla awo okusingatha izinsalela ezikhulayo kanye nezicelo zokuhlukanisa isitimu zomjikelezo ohlangene, njengoba abaklami beqhubeka nokuphusha ubhayela, i-HRSG, kanye nezimvilophu zengcindezi/izinga lokushisa lamapayipi. Amavaluvu ophawu lokucindezela ngokuvamile atholakala ngosayizi ukusuka kumayintshi angu-2 ukuya kwangu-24 amayintshi kanye nezigaba zokucindezela ze-ASME B16.34 ukusuka ku-#600 ukuya ku-#2500, nakuba abanye abakhiqizi bengakwazi ukwamukela isidingo samadayimitha amakhulu kanye nezilinganiso eziphakeme zezinhlelo zokusebenza ezikhethekile.

Amavalvu ophawu lokucindezela ayatholakala ngezimfanelo eziningi ezibonakalayo ezifana ne-A105 efojiwe kanye ne-Gr.WCB cast, ingxubevange engu-F22 efojiwe kanye ne-Gr.WC9 cast; I-F11 eyakhiwe kanye ne-Gr.WC6 cast, i-austenitic stainless F316 eyakhiwe kanye ne-Gr.CF8M cast; ngaphezu kuka-500 ° C, F316H amamaki afojiwe futhi afanelekile we-austenitic cast.

Umqondo wokuklama uphawu lokucindezela ungalandelelwa emuva maphakathi nawo-1900s, lapho, bebhekene nezingcindezi ezikhuphuka njalo namazinga okushisa (ikakhulukazi ekusetshenzisweni kwamandla), abakhiqizi bamavalvu baqala ukuklama ezinye izindlela zendlela yeBonnet yendabuko yokuvala ilunga lomzimba/Ibhonethi. . Ngokuhambisana nokuhlinzeka ngezinga eliphezulu lobuqotho bokuvalwa komngcele wengcindezi, imiklamo eminingi ye-valve yophawu lokucindezela inesisindo esingaphansi kakhulu kunozakwabo ababolithiwe be-Bonnet Valve.

Amabhonethi Abhontshisiwe vs. Izimpawu Zokucindezela

Ukuze uqonde kangcono umqondo womklamo wophawu lokucindezela, ake siqhathanise indlela yokuvala umzimba nebhonethi phakathi kwamabhonethi abhawudi kanye nezinsimbi zokucindezela.Umdwebo 1ikhombisa ivalvu yebhonethi eboshiwe ejwayelekile. I-flange yomzimba kanye ne-Bonnet flange kuhlanganiswe izigxobo namantongomane, nge-gasket yedizayini efanelekile/impahla efakwe phakathi kobuso be-flange ukuze kube lula ukuvala. Izigxobo/amantongomane/amabhawodi aqiniswa kuma-torque anqunyiwe ngephethini echazwe umkhiqizi ukuze kuthinte ukuvalwa kahle. Kodwa-ke, njengoba ingcindezi yesistimu ikhula, amathuba okuvuza ngokuhlanganyela komzimba/Ibhonethi nawo ayanda.

Manje ake sibheke inhlanganisela ye-pressure seal enemininingwane kuyoUmdwebo 2Qaphela umehluko ekucushweni okuhlangene komzimba/ibhonethi. Imiklamo eminingi yophawu olucindezelayo ihlanganisa “amabhawodi okuthathwa kwebhonethi” ukuze adonsele iBonnet phezulu futhi avale ngokumelene ne-pressure seal gasket. Lokhu kudala uphawu phakathi kwe-gasket kanye nedayari yangaphakathi (ID) yomzimba we-valve.

I-thrust ring ehlukene igcina umthwalo. Ubuhle bomklamo we-pressure seal ukuthi njengoba ingcindezi yesistimu ikhula, kanjalo nomthwalo ku-Bonnet kanye, ngokufanayo, i-gasket seal yokucindezela. Ngakho-ke, kuma-valve ophawu lokucindezela, njengoba ingcindezi yesistimu ikhula, amandla okuvuza ngomzimba/ijoyinti yebhonethi ayancipha.

Le ndlela yokuklama inezinzuzo ezihlukile kunamavalufu e-Bonnet abholithiwe kusitimu esikhulu, amanzi okuphakelayo, i-turbine bypass, nezinye izinhlelo zesikhungo samandla adinga ama-Valves akwazi ukubhekana nezinselele ezikhona ekusetshenzisweni kwengcindezi ephezulu kanye nezinga lokushisa.

Kodwa ngokuhamba kweminyaka, njengoba izingcindezi zokusebenza/izinga lokushisa zikhula, futhi ngokufika kwezitshalo eziphakeme kakhulu, le ngcindezi yesistimu yesikhashana efanayo eyasiza ekuvaleni iphinde yadlala isiphithiphithi ngobuqotho obuhlangene bophawu lokucindezela.

I-Pressure Seal Gaskets

Enye yezingxenye eziyinhloko ezihilelekile ekuvaleni i-Valve ye-pressure seal yi-gasket ngokwayo. Ama-gaskets angaphambi kwesikhathi akhiqizwa ngensimbi noma ngensimbi ethambile. Lawa ma-gaskets abe esecwetshwa ngesiliva ukuze asebenzise ikhono lezinto ezithambile zokunamathisela ukuze anikeze uphawu oluqinile. Ngenxa yengcindezi esetshenziswa ngesikhathi se-Valve's hydrotest, "isethi" (noma ukuguqulwa kwephrofayili ye-gasket) phakathi kweBonnet ne-gasket yathathwa. Ngenxa yebholithi engokwemvelo yokuthatha i-Bonnet kanye nokunwebeka kwejoyinti ye-pressure seal, amandla okuthi I-Bonnet inyakaze futhi iphule leyo “sethi” lapho ingaphansi kwengcindezi yesistimu iyenyuka/ukuncipha abekhona, nokuvuza kwelunga lomzimba/Ibhonethi.

Le nkinga ingase ixazululwe ngokuphumelelayo ngokusebenzisa umkhuba "wokushisa okushisayo" amabhawodi okuthatha i-Bonnet ngemva kokucindezelwa kwesistimu nokulingana kwezinga lokushisa, kodwa kwakudinga abasebenzi bokunakekela umnikazi/umsebenzisi ukuthi benze kanjalo ngemva kokuqala kwesitshalo. Uma lo mkhuba ungazange ulandelwe, amathuba okuvuza ngejoyinti lomzimba/yebhonethi ayekhona, okungalimaza i-pressure seal gasket, i-Bonnet kanye/noma i-ID ye-Valve body, kanye nokudala izinkinga ezihlanganisayo kanye nokungasebenzi kahle ukuvuza kwesitimu kungaba nakho ekusebenzeni kwezitshalo. Ngenxa yalokho, abaklami be-Valve bathathe izinyathelo ezimbalwa zokubhekana nale nkinga.

Umfanekiso wesi-2 ubonisa inhlanganisela yamabhawodi okuthatha i-Bonnet alayishwe bukhoma (ngaleyo ndlela igcina umthwalo ongashintshi ku-gasket, kunciphisa amandla okuvuza) kanye nokushintshwa kwensimbi/insimbi ethambile, i-silverplated pressure seal gasket ngeyodwa eyenziwe nge-die- i-graphite eyakhiwe. Idizayini ye-gasket eboniswe kuMfanekiso 3 ingafakwa ku-pressure seal Amavalvu ayehlinzekwe ngaphambili nohlobo lwe-gasket yendabuko. Ukufika kwama-graphite gaskets kuye kwaqinisa nakakhulu ukwethembeka nokusebenza kweValve yophawu lokucindezela ezinhlelweni eziningi kanye nemijikelezo yokusebenza yansuku zonke yokuqala/yokumisa.

Nakuba abakhiqizi abaningi besancoma “i-hot torquing,” amandla okuvuza uma lokhu kungenziwa ancipha kakhulu. Izindawo zokuhlala ezisezindaweni zokucindezela ama-Valves, njengasezindaweni eziningi zamandla kagesi Amavalvu, angaphansi, uma kuqhathaniswa, imithwalo yezihlalo ephezulu kakhulu. Ubuqotho bezihlalo bugcinwa njengomsebenzi wokubekezelela okuqinile kwemishini ezingxenyeni zezingxenye, izindlela zokuhlinzeka ngetorque edingekayo ukuze uvule/uvale njengomsebenzi wamagiya noma ukuqalisa, kanye nokukhetha/ukusetshenziswa kwezinto ezifanele zezindawo zokuhlala.

I-cobalt, i-nickel, nama-alloys e-hardfacing asekelwe ku-iron asetshenziselwa ukumelana nokugqokwa kwe-wedge/idiski nendawo yokuhlala indandatho. Okuvame ukusetshenziswa kakhulu yi-CoCr-A (isb, i-Stellite) materials. Lezi zinto zisetshenziswa ngezinqubo ezahlukahlukene, kufaka phakathi i-arc yensimbi evikelekile, i-gas metal arc, i-gas tungsten arc, ne-plasma (edluliselwe) arc. Amavalvu amaningi okucindezela i-Globe aklanywe ukuthi abe nezihlalo ezinobuso obuqinile, kuyilapho i-Gate Valve kanye nama-Check Valves ngokuvamile anezindandatho zezihlalo ezinobuso obuqinile ezishiselwe emzimbeni weValve.

I-Valving terminology

Uma uke wabhekana ne-valve nganoma yisiphi ubude besikhathi, kungenzeka ukuthi uqaphele ukuthi abakhiqizi be-Valve abaqambi ngokweqile imigomo nezilimi zomdabu ezisetshenziswa ebhizinisini. Thatha isibonelo, "ama-Bonnet Valves". Umzimba uboshelwe kuBonnet ukuze ugcine ubuqotho besistimu. Kuma "Valves seal yokucindezela," ingcindezi yesistimu isiza indlela yokuvala. Kokuthi "Misa/Hlola Amavalvu," lapho isiqu seValve sisendaweni evaliwe, ukugeleza kumiswa ngokuzenzekelayo, kodwa uma isendaweni evulekile, idiski ikhululekile ukusebenza ukuze ihlole ukuhlehla kokugeleza. Lo mgomo ofanayo uyasebenza nakwamanye amagama asetshenziselwa ukuklama, kanye nezinhlobo zeValve nezingxenye zazo.

Isikhathi sokuthumela: May-11-2020